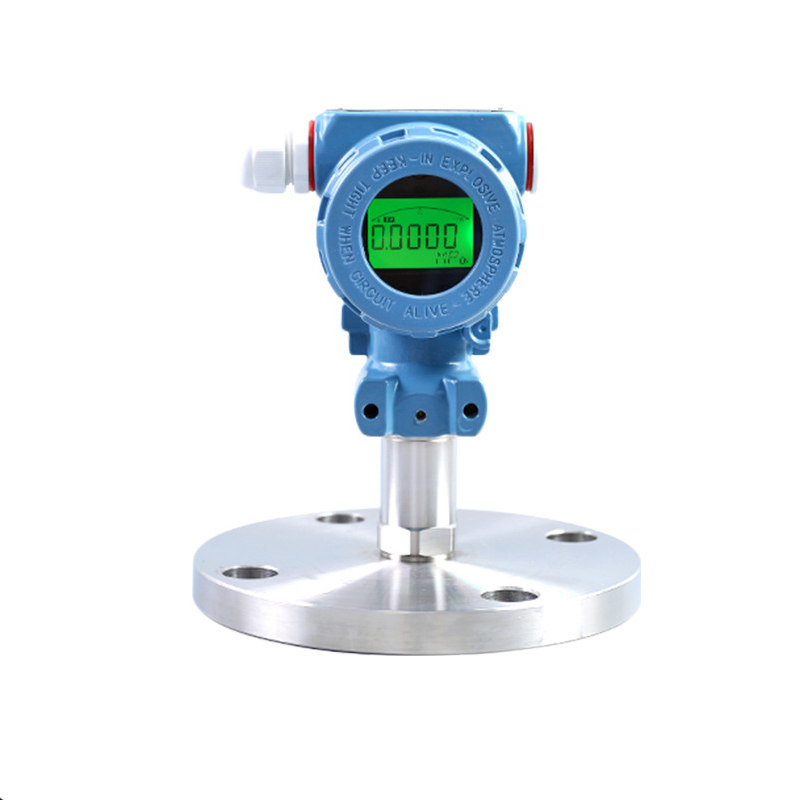

Products Description

PCM-250 flush diaphragm pressure transmitter is a kind of solid flattened diaphragm with special treatment at the measuring terminal,hard particles in the measured medium will not damage the isolated flattened diaphragm. Compact structure, corrosion resistance,vibration resistance, corpuscle impact resistance, wide range temperature compensation. It is especially suitable for the measurement of fluid pressure of high viscous substances or with particulates. It solves the problem of medium blockage in the pressure tapping hole. 520 series low range LED on-site display pressure transmitter adopts the advanced electronic ceramic technology in the world to measure the dielectric-free liquid in the components. The 530 medium and high temperature pressure transmitter is assembled with imported high temperature resistant sensitive elements. transducer probe can work stably for a long time at 150℃. All three products both have the characteristics of overload resistance, strong impact resistance, good linearity, long-term stability, wide temperature range and corrosion resistance. Used in hydraulic, military, scientific research, aerospace, petroleum, chemical industry, electric power, ocean and other fields.

| Range | -100~0~5,100,500,800,1000KPa;0~2,10~40MPa | ||

| Pressure type | Gauge pressure, negative pressure and absolute | ||

| Output signal | 4~20mA, 0.5~4.5V | ||

| Input voltage | 12~36V DC (5V) | ||

| Accuracy | 0.1 | 0.2(0.25) | 0.5 |

| Nonlinear Repeatability Delaying | 0.1 | 0.2(0.25) | 0.5 |

| Zero and sensitivity | 0.01 | 0.02(0.025) | 0.005 |

| Temperature | -10℃~+70℃ | ||

| Work temperature | -40~+150℃ | ||

| Long-term | ≤0.1±%FS/year | ||

| Response time | <1ms | ||

| Overload capacity | 200% | ||

| Measurement medium | Corrosive media compatible with 316L | ||

| Diaphragm | 316L stainless steel, heusler alloy C-276 | ||

| Case material | 1Cr18Ni9Ti | ||

| Protection rating | IP67 | ||

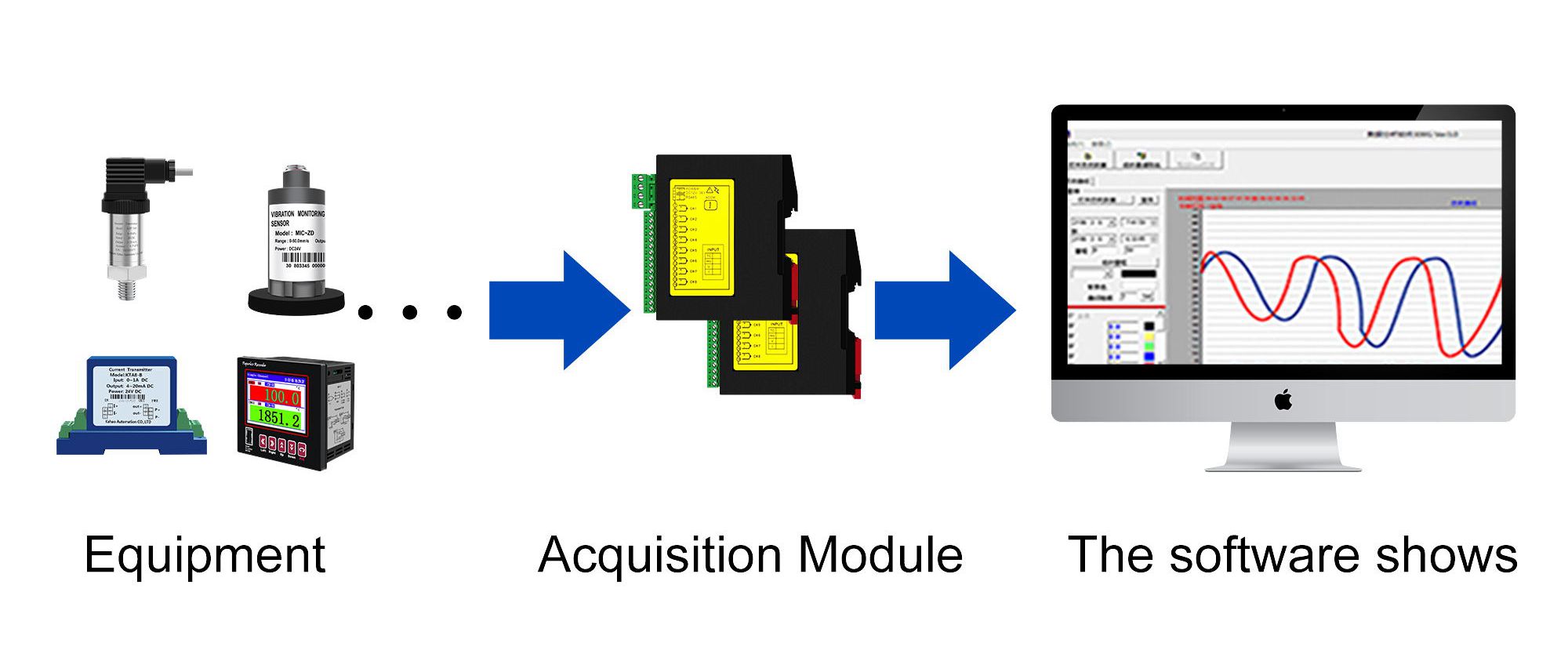

Device real-time monitoring query

The equipment uses RS485 communication connection acquisition card to achieve real-time recording, monitoring and query